产品详情

一家专注于高合金钢锻件的生产,研发,销售于一体的特殊钢企业

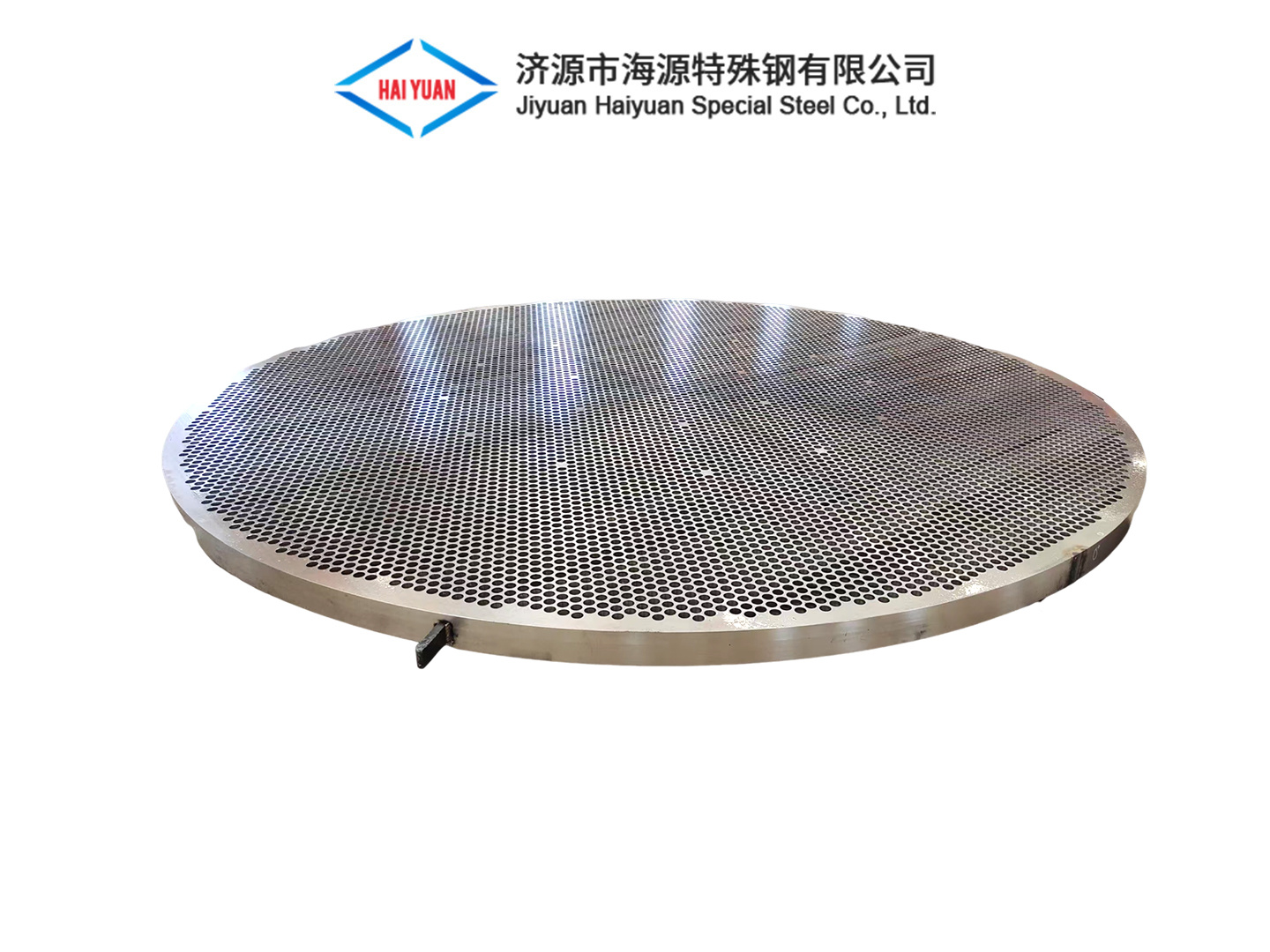

管模

铸管模产品介绍

Introduction of Pipe Mould

一、工艺流程 Process Flow Chart

炼钢 → 精炼 → 锻造 → 无损检测 → 热处理 → 无损检测 → 精加工 → 无损检测 → 交货

Steelmaking → Refining → Forging → NDT → Heat Treatment → NDT → Finish Machining → NDT → Consignments

- 炼钢工艺:EB T+LF/VD

- 锻造设备:油压机或精锻机(一次锻造成型)

- 无损检测标准:JB/ T1581-96 超声波探伤

- 热处理:调质处理(淬火 + 回火)+ 去应力处理

- 精加工设备:数控车床

二、产品概况 Product Overview

- 产品类型:

- T 型水冷金属型管模

- S 型、N 型、K 型热模法管模

- T 型水冷金属型管模

- 材质:15Cr2Mo、21CrMo10、30CrMo

- 产品规格:管径 DN80-1200mm,长度 3-6m

- 年产能:2000 支(各类离心球墨铸铁管管模)

- 产品优势:使用寿命与美国、德国进口产品相当

英文对照

We provide T-tube-type water-cooled metal molds, S-type, N-type and K-type thermal tube molds made from 15Cr2Mo, 21CrMo10 and 30CrMo. The product size ranges from DN80 to 1200mm with a length of 3-6m, and the annual production capacity is 2000 pieces for various ductile iron pipe moulds. With the same service life as products made in America and Germany.

三、工艺特点 Process Features

- 严格控制冶炼过程:准确调控硫(S)、磷(P)、氢(H)、氧(O)含量,可按客户要求控制铅(Pb)、锡(Sn)、铋(Bi)等残余有害元素含量。

- 铸锭工艺:采用钢锭下铸法,大型钢锭优化收缩比,保证钢的致密性、纯度,减少非金属夹杂物。

- 夹杂物评级:按 GB/ T10561-2005 中 ISO 评级图判定,A、B、C、D、Ds 类夹杂物均不大于 2.0 级(取严重者判定)。

英文对照

Our company leverages unique forging equipment, adjusts element content, and strengthens process control. During steel melting, we strictly control the contents of S, P, H, O, and limit harmful elements such as Pb, Sn, Bi as required by customers. We adopt bottom pouring for ingot casting and optimize the shrinkage ratio of large ingots to ensure steel purity and compactness, reducing nonmetallic inclusions. Inclusion testing is conducted in accordance with GB/T10561-2005, and the rating of A, B, C, D types shall be ≤2.0 (judged by the worst case).

四、化学成分 Chemical Composition (mass %)

牌号 Grade | 碳 C | 硅 Si | 锰 Mn | 铬 Cr | 钼 Mo | 镍 Ni | 铜 Cu | 磷 P | 硫 S |

15Cr2Mo | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 2.30-2.60 | 0.40-0.55 | <0.35 | <0.15 | <0.009 | <0.009 |

21CrMo10 | 0.16~0.23 | 0.20~0.40 | 0.20~0.40 | 2.20~2.60 | 0.30~0.50 | <0.50 | <0.15 | <0.009 | <0.009 |

30CrMo | 0.23-0.30 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | <0.50 | <0.15 | <0.009 | <0.009 |

注:可根据需方要求控制铅、砷、锡、锑、铋等残余有害元素含量。

Note: The contents of harmful elements such as lead, arsenic, tin, antimony, bismuth can be controlled according to the purchaser's requirements.

五、力学性能 Mechanical Property

牌号 Grade | 抗拉强度 Rm (MPa) | 屈服强度 Rp0.2 (MPa) | 延伸率 A (%) | 断面收缩率 Z (%) | 冲击功 Akv (J) | 布氏硬度 HBW |

15Cr2Mo | 780 | >680 | >12 | >50 | >78 | >230 |

21CrMo10 | 780 | >650 | >16 | >60 | >78 | >240 |

30CrMo | 780 | >680 | >10 | >35 | >21 | >200 |

注:管模全长布氏硬度差不大于 40HBW。

Note: The maximum hardness difference for the full-length pipe mould shall be no more than 40HBW.

六、T 型水冷金属型管模主要尺寸 The Size of T-tube-type Water-cooled Metal Mold (mm)

管径 DN | L1 | L2 | L3 | D1 | D2 | D3 | D4 | D5 | D6 | 重量 (kg) |

80 | 6287 | 27 | 6129 | 270 | 205 | 164.7 | 97.2 | 164 | 183 | 530 |

100 | 6287 | 27 | 6129 | 270 | 205 | 164.7 | 116.8 | 164 | 183 | 400 |

150 | 6287 | 27 | 6129 | 325 | 266 | 217 | 168.9 | 209 | 209 | 605 |

200 | 6287 | 27 | 6129 | 385 | 325 | 281 | 221.1 | 261 | 288 | 764 |

250 | 6287 | 27 | 6129 | 455 | 385 | 336 | 273.4 | 320 | 340 | 1112 |

300 | 6287 | 27 | 6129 | 520 | 443 | 393.9 | 325.2 | 376 | 387 | 1434 |

350 | 6341 | 37 | 6169 | 575 | 495 | 448 | 378 | 444 | 450 | 2045 |

400 | 6341 | 37 | 6169 | 615 | 550 | 502 | 429 | 494 | 502 | 2416 |

500 | 6341 | 37 | 6169 | 755 | 663 | 606.5 | 532.1 | 608 | 610 | 3557 |

600 | 6348 | 44 | 6169 | 850 | 790 | 716.1 | 635.3 | 715 | 730 | 4274 |

700 | 6348 | 44 | 6169 | 970 | 902 | 828 | 738.5 | 828 | 835 | 5838 |

800 | 6600 | 118 | 6180 | 1148 | 1013 | 948.4 | 843.5 | 940 | 930 | 7269 |

900 | 6600 | 181 | 6180 | 1258 | 1123 | 1058 | 947.5 | 1063 | 1060 | 9800 |

1000 | 6600 | 181 | 6180 | 1350 | 1233 | 1165 | 1051 | 1166 | 1160 | 10516 |

1200 | 6435 | 44 | 6281 | 1585 | 1447 | 1388 | 1257 | 1375 | 1372 | 12675 |

七、T 型水冷金属型管模结构型式 The Structure of T-tube-type Water-cooled Metal Pipe Mold

咨询